| Sign In | Join Free | My chinalane.org |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My chinalane.org |

|

Brand Name : LIJIANG GLASS

Model Number : LJTB01

Certification : CE

Place of Origin : JINAN CHINA

MOQ : 1 set

Price : negotiable

Payment Terms : L/C, T/T

Supply Ability : 50 sets per month

Delivery Time : 15 days

Packaging Details : wooden box

Product name : butyl glue extrusion coating machine

Application : double glazing glass processing

Heating time : 15 mins

Squeeze Pressure : 10-25MPa

Speed : 0-47m/min

Voltage : 380V 50Hz 3P

squeeze pressure : 10-18MPa

Glue thickness : 0.3-0.5mm

Aluminum spacer width : 5.5-26.5mm

Weight : 750KG

Overview of butyl gule extrusion coating machine

LJTB01 Butyl Extruder is special equipment for the production of double-glazed glass. As one of the important equipment in the production of insulating glass, the effect of butyl glue is directly related to the waterproofing of the insulating glass. The equipment is automatic, easy to use, and convenient to use.

The glue butyl extrusion machine is used to evenly distribute the aluminum spacer frames with hot melt butyl. The operation of the butyl extruder is easier than before, it uses a large electric control panel. The aluminum conveyor is controlled by a frequency converter. The speed can be adjusted from 0m / min to 47m / min.

Tech parameters of high-speed butyl extruder machine

| Squeeze pressure | 10-25MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight7 | 50kg |

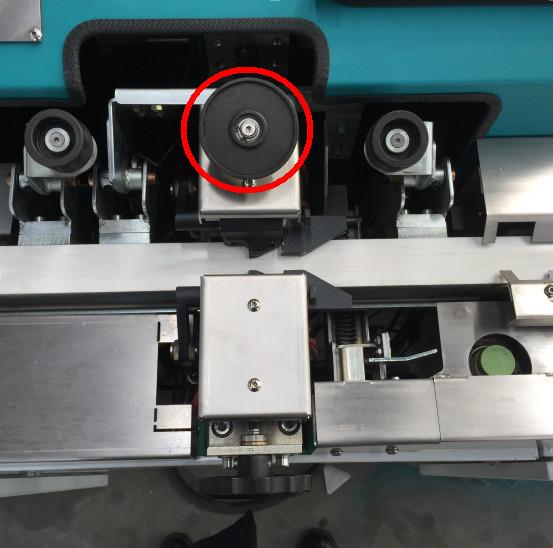

Equipment details of automatic butyl coating machine

1.Germany Siemens parts

Adopt Siemens brand, stable performance.

3.Fast coating speed,can up to 47m/min

4.Germany HAVE Valve

Adopt Germany’s Harvey valve, more stable performance.

5.KINCO Touch Screen

Clear interface, Simple operation, Smart touch screen,Updated programming.

6.Alarm system

Automatically alarm system, reminding adding butyl.

7.Germany Maximator Cylinder

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

8.Glue cylinder Adopt the upright structure, easy to change butyl.

Detail picture

Optional functions of butyl coating machine:

200L glue cylinder is optional

Related Product

Automatic spacer bending machine LJZW2020

Automatic spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Equipment details

Technical data

| Max.bending size | 2000mm*2000mm (2500mm*2500mm) |

| Min.bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | ≤26s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

Related product

1.Manual Gas Filling Machine LJCJ02N

Main feature

• It is used for filling Argon into insulating glass

• High effectively, allowed for four pieces of IGU

• When the gas is full,it will alarm and stop automatically

• Can set and display the data of gas value

Technical data

| Power supply | 220V 50Hz |

| Total power | 0.1kw |

| Dimension | 620*439*700mm |

2.Cantilever crane LJXJ300

Technical data

| Max.load | 300kg |

| Rotated angle | 90° |

| Upright height | 3400mm or 3900mm |

| Rail length | 1000mm |

| Quantity of sucker | 2 or 4 |

| Air pressure | 0.5MPa-0.8MPa |

|

|

IGU 10MPa Butyl Extruder Machine Double Glazing Glass Processing Images |